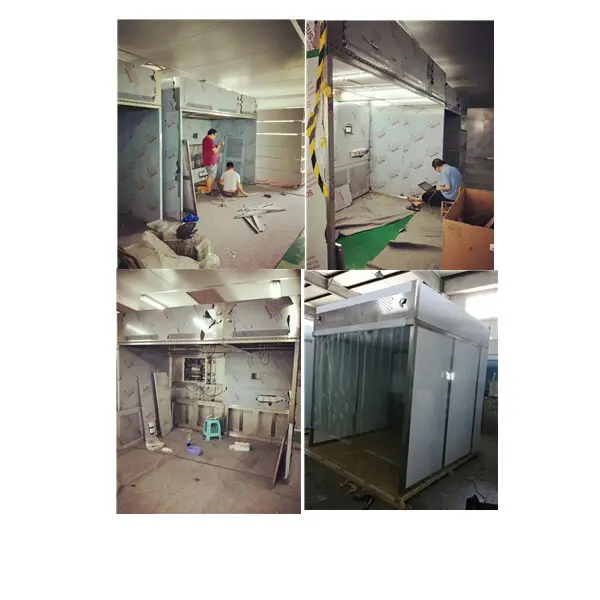

We have a team that benefits from over 15 years cleanroon equipment fieldwork and experience.

negative pressure dispensing booth gmp modular design for pharmaceutical factory

- With a complete service system, HaoAir is dedicated to providing consumers with comprehensive and thoughtful services.

1. During the production, the quality of HAOAIRTECH dispensing unit is strictly scrutinized in terms of materials, cutting, welding, turning, milling, grinding, and surface treatment.

2. The product is resistant to weather resistance. It is able to withstand sunlight, temperature, ozone, and inclement weather conditions (rain, hail, sleet, snow, etc.).

3. The product features high accuracy. All its parts have been measured by means of the advanced 3D coordinate measuring device.

4. The product matches perfectly with walls painted in rich, light, or dark colors. Anyway, because of its delicate design, it works harmoniously with space style.

Introduction:

The dispensing booth is a local purification device for pharmaceutical, microbiological research and scientific experiments.

It provides a vertical unidirectional airflow. Part of the clean air circulates in the working area and is partially discharged to the nearby area to make the working area negative pressure to prevent cross-contamination and to ensure a high cleanliness environment in the work area.

Dust, reagent weighing and dispensing in the dispensing booth can control dust, reagent spillage and uplift, prevent dust and reagents from inhaling harm to the human body, avoid cross-contamination of dust and reagents, and protect the environment and indoor personnel.

The weighing operating area is protected by a thousand vertical laminar flow ISO 6 (NF, EN, ISO 14644-1).

Features:

1.the special air dust design with a high performance at decrease the noise.

2.the air out let operate system can control the powder and reagent over flowing or raise. prevent the powder and reagent cross infection.protect the worker out of harmful.

3.pressure guage will monitor the HEPA air filter situation.

4.humanization design for your easy to change the HEPA air filter.

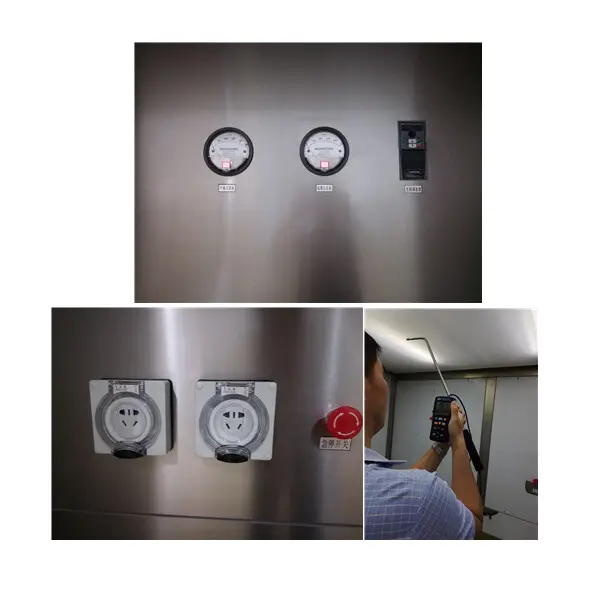

Product Details:

1.The order from left to right is the differential pressure gauge of the medium efficiency filter, the differential pressure gauge of the high efficiency filter and the frequency converter.

An initial filter differential pressure gauge and LED display can also be installed.

2.This is the socket and emergency stop switch.

3.The wind speed in the dispensing booth is constant, which is 0.63m/s.

Product parameters:

MODEL | HA-DB1000 | HA-DB1500 | HA-DB2000 |

External size (mm) (W*D*H) | 1200x1500x2400mm | 1500x1700x2400mm | 2000x1800x2400mm |

Work zone (mm) (W*D*H) | 1100x1200x2000mm | 1400x1200x2000mm | 1900x1300x2000mm |

Purification rank | Class 100(ISO5) | ||

Air speed | 0.2-0.7m/s | ||

Material (Option) | 1: Entirety Stainless Steel 201/304/316.(T=1.2/1.5mm) 2: External and internal side is steel with power coated. (T=1.2/1.5mm) | ||

Control system | 1: Air Speed according to frequency converter control . 2: Gel Sealant High Efficiency HEPA air filter for high purification rank 3: Wind speed detection, Constant temperature and constant humidity Detector according to client request install 4: DOP/PAO Port and differential Pressure Guage for HEPA /secondary filter so that remind of you change the air filter in time 5: 5 different filter configuration available utilizing combination of G4,F8.H13,H14 and PLF Screens . 6; GMP Modular design with minimized joints and seams. 7: PVC strip curtains available 8; Energy Efficient high air volume fan to minimize operating cost, | ||

Noise level(dB) | <65dB | ||

Filter step | 3 Step | ||

HEPA filter | 99.995% @ 0.3um Gel sealant mini--pleats HEPA Air Filter | ||

Secondary filter | F8 pocket air filter | ||

Pre-filter Efficiency | 75%@5um | ||

Power supply | 380V/50HZ OR 220V/50HZ | ||

Packing material | Standard Export Poly wood Packing(Fumigant free material) | ||

Customer's design is available.

Company Features

1. Guangzhou HaoAir Purification Technology Co.,Ltd. takes pride in developing and manufacturing dispensing unit . We have become very competitive in the field.

2. Our technical support engineers have deep industry and technical knowledge of dispensing booth .

3. Following the principle of downflow booth , HAOAIRTECH will create more environment-friendly products. Ask! Guangzhou HaoAir Purification Technology Co.,Ltd. will highly value the importance every detail. Ask! The essence of keeping HAOAIRTECH forward is sampling booth . Ask!

Email: sales2@haoairtech.com

Add: RM323 KaiSheng Building,CongYun RoadYongping street ,Baiyun District, Guang Zhou, Guangdong, China