We have a team that benefits from over 15 years cleanroon equipment fieldwork and experience.

HAOAIRTECH plc control system air showers and pass thrus with top side air flow for pallet cargo

-

v s

1. HAOAIRTECH air shower is designed from a group of innovative engineers.

2. Excellent color retention is one of its advantages. It is dyed finely to the designated degree of saturability it does not need to take any more dye.

3. It receives a double reputation from customers and the market.

External Material: stainless steel304 (t=1.0) Or steel with milk color power coated

Inside Material: stainless steel304 (t=1.0)

External size: 1400*1000*2180mm

Internal size: 790*930*1910mm

Sus nozzle: 16pcs

Blowing way: one side (top)

Air speed: more than 25m/s

Door: Electric Interlocking in both side.

MODEL | HA-AS1400V1 | HA-AS1400V2 | HA-AS1400V3 | |

External size (mm) | 1400x1000x2180 | 1400x2000x2180 | 1400x3000x2180 | |

Work zone (mm) | 790x930x1910 | 790x1930x1910 | 790x2930x1910 | |

Persons per cycle | 1-2 person | 2-4 person | 3-6 person | |

Material (Option) | 1:Entirety Sus304.(T=1.0/1.2/1.5mm) | |||

Control system | 1: Control system with LED display for the shower time. | |||

The power of fan | 380V/50HZ/1.1KW | 380V/50HZ/1.1KW | 380V/50HZ/1.1KW | |

Air flow of fan(m3/h) | 1500 | 1500 | 1500 | |

Fan run (r/min) | 2800 | 2800 | 2800 | |

Nozzle in stain less steel | 16 pcs | 32 pcs | 48pcs | |

Wind speed(m/s) | >25m/s | |||

Noise level(dB) | <75dB | |||

HEPA FILTER | Size(mm) | 630X630X80mm | 630X630X80mm | 630X630X80mm |

Efficiency (%) | 99.995% @ 0.3um Mini-pleats HEPA air filter | |||

Air velocity | 1000m3/h | |||

Initial resistance(pa) | <220pa | |||

Pre-filter | Size(mm) | 775x380x17 | 775x380x17 | 775x380x17 |

Efficiency(%) | 75% @ 0.5um | 75% @ 0.5um | 75% @ 0.5um | |

G3 | G3 | G3 | ||

resistance(pa) | <30 Pa | <30Pa | <30 Pa | |

parameter | Power supply | 380v/50Hz | 380v/50Hz | 380v/50Hz |

Net power(kw) | 1.5 kw | 3kw | 4.5 kw | |

packing size (mm) | 1500x1200x2250 | 1500x2200x2250 | 1500x3200x2250 | |

Packing material | Standard Export Poly wood Packing(Fumigant free material) | |||

Weigh | 320kgs | 650kgs | 960kgs | |

Illustrate

1: Control board 2: Infrared Indicator 3: Per-filter 4: Power Indicator 5: Emergency switch 6: Working light 7: HEPA air filter (H13 99.995%@0.3um) 8: Door 9: Fan 10: Door Closer 11: Nozzle 12: Purification light

Application

Clean room air shower products are a kind of local cleaning equipment with strong versatility. They are installed between clean rooms and non clean rooms. It has been applied in many fields, such as food and beverage, biochemistry, precision instrument, electronic, photoelectric, microelectronics, fiber optic cable, precision machinery, biopharmaceutical, aeronautics and Astronautics and so on.

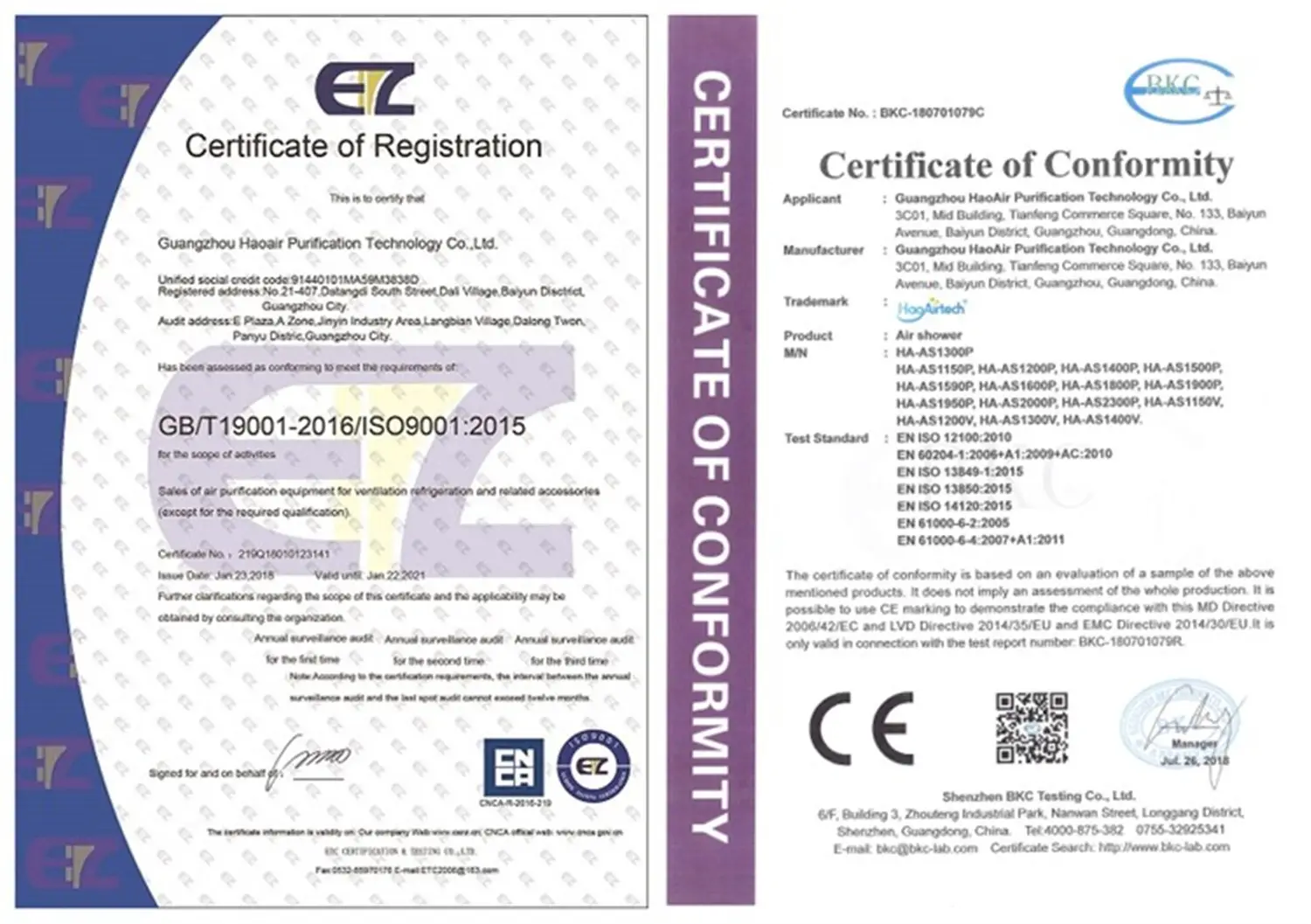

/ Certificated

Our Service

1:Document

A: Document for custom clear: 1 sets

B: Assemble draw: 1 pcs

C: Circuit diagram draw: 1 pcs

D: Test report : 1sets

E: Additional IQ/OQ/PQ document is available upon request.

2: Air Shower Spare Part so that you can replacement in future by yourself:

A: HEPA air filter +Pre-filter (as your request)

Note: HEPA air filter should be replacement in half and one year. Pre-filter

should be replacement in each 6 months, but it can refresh no more than 3 times

B: Sensor (As your request)

C: Control board (as your request)

3: The air shower guarantee time is 2 years excluding consumable parts and accessories .

Company Features

1. Guangzhou HaoAir Purification Technology Co.,Ltd. is a technology-intensive enterprise specializing in the production and sales of air shower .

2. Our factory is equipped with state-of-the-art production facilities. They are of high precision and high efficiency, which ensures that our products are made to specification and high quality.

3. We are committed to consistently promoting our brand in the communication and marketing of all audiences – connecting customer needs and stakeholder expectations, and building a belief in our future and value. Contact us! Our companies align ourselves with a social cause. We concern the development of our society. We devote to supplying communities with capitals or resources if there are any natural disasters happen. Contact us! Guangzhou HaoAir Purification Technology Co.,Ltd. is dedicated to growing air shower manufacturer with reduced cost but high quality. Contact us!

1.Pearl cotton or foam bags package

2.PE film package

3.Paper cartons package

4.Wooden cases package Or as per customer requirements

| Process of making moulds | |

| 1.Sample/Drawing | After receiving your detail information like 2D & 3D drawings or sample for reference, will pass to R&D team to do moldflow analysis. |

| 2.Negotiation | Material, cavity, price, delivery time, payment term etc. |

| 3.Place Order | when all terms are agreed by both sides, then we will accept an order. |

| 4.Mould Design | Our R&D team will design the mould per customer requirements and send drawings for approval. |

| 5.Tooling Mould | Once the mould design is approved will start mould tooling. |

| 6.Mould Process | CNC grinding and milling, Heat Treatment, Wire Cut, Polish, Tool assembling and testing etc. Our good QC system can guarantee the product quality. |

| 7.Sample Confirmation | Send sample for confirmation, if not approved we will adjust the mould structure. |

| 8.Mass Production | After customer approves the sample, we will arrange mass production. QC will inspect after products finished. |

| 9.Package | PE film for plastic parts,wooden case for moulds or as customer's requirement. QC will inspect packing. |

| 10.Delivery | By sea or by air according to customer requirement. |

| 11.After-sales Service | Ready to help customers solve any possible problems. |

Email: sales2@haoairtech.com

Add: RM323 KaiSheng Building,CongYun RoadYongping street ,Baiyun District, Guang Zhou, Guangdong, China