We have a team that benefits from over 15 years cleanroon equipment fieldwork and experience.

HAOAIRTECH plc control cleanroom pass box with baked painting for hvac system

1. HAOAIRTECH static pass box specification must go through these following production stages, including metal materials procurement and preparation, components machining, surface polishing, and assembly.

2. Products under the supervision of professionals, through strict quality inspection, to ensure product quality.

3. We can provide all relative certificates for our cleanroom pass box for your reference.

4. You give trust our cleanroom pass box and we will give good quality in return.

Internal size: 600*600*600mm

External Material: stainless steel304 (t=1.0)

Inside Material: stainless steel304 (t=1.0)

Electric interlocking or mechanical interlocking

MODEL | HA-NPB500 | HA-NPB600 | HA-NPB700 |

External size (mm) | 660x500x590mm | 760x600x690mm | 860x700x790mm |

Work zone (mm) | 500x500x500mm | 600x600x600mm | 700x700x700mm |

Material | 1: Entirety Sus304.(T=1.0/1.2mm) | ||

Control system | Electric interlocking or mechanical interlocking | ||

UV light | 1 PCS | ||

Power supply | 220v/50HZ | ||

packing size (mm) | 800x870x850mm | 1000x870x940mm | 1100x970x1050mm |

Packing material | Standard Export Poly wood Packing(Fumigant free material) | ||

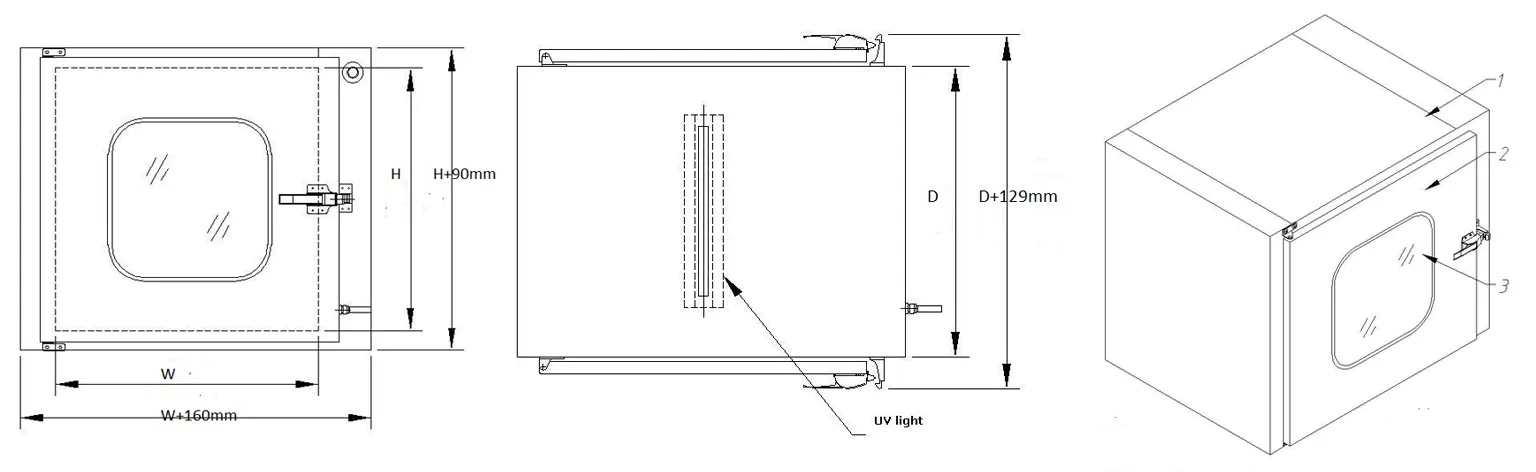

Illustration

1: Cabinet 2: Door 3: Glass dorr(6mm)

Introduce

The pass box is a kind of auxiliary equipment in clean room. It is mainly used in the transmission of small pieces goods between clean area and clean area, clean area and unclean area, so as to reduce the clean room door open time and reduce the clean room pollution to the lowest level, The pass box is made of stainless steel plate, smooth and clean. The both doors are interlinked, effectively preventing cross contaminated, electronic or mechanical interlocking devices installed , and fixed with ultraviolet lamps so that eliminate the bacterial infection

/ Certificated

Our Service

1:Document

A: Document for custom clear: 1 sets

B: Assemble draw: 1 pcs

C: Circuit diagram draw: 1 pcs

D: Test report : 1sets

E: Additional IQ/OQ/PQ document is available upon request.

2: Air Shower Spare Part so that you can replacement in future by yourself:

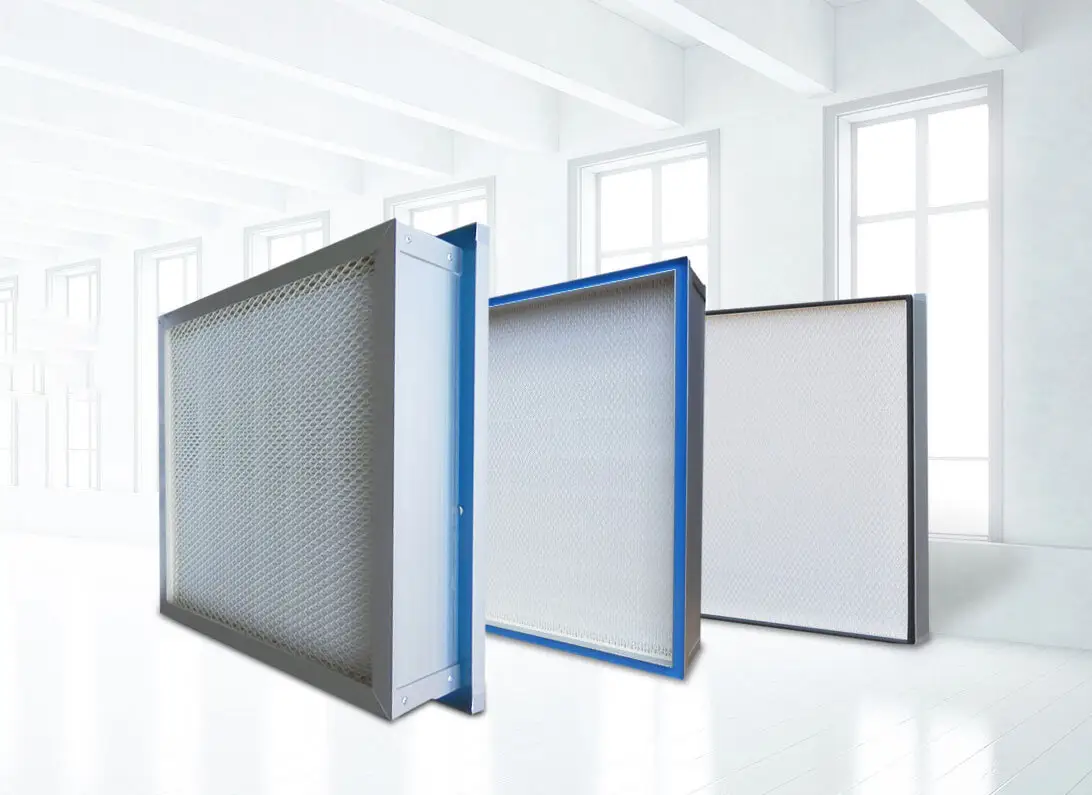

A: HEPA air filter +Pre-filter (as your request)

Note: HEPA air filter should be replacement in half and one year. Pre-filter

should be replacement in each 6 months, but it can refresh no more than 3 times

B: Sensor (As your request)

C: Control board (as your request)

3: The air shower guarantee time is 2 years excluding consumable parts and accessories .

Company Features

1. Our premium materials ,advanced technology and craftsmanship can definitely ensure high quality cleanroom pass box .

2. Guangzhou HaoAir Purification Technology Co.,Ltd. has introduced advanced R&D and production equipment.

3. HAOAIRTECH holds the belief that by advocating enterprise culture, the cohesion in the company will promote the growth of a company. Contact! To HAOAIRTECH, there is no border for excellence in quality. Contact!

Email: sales2@haoairtech.com

Add: RM323 KaiSheng Building,CongYun RoadYongping street ,Baiyun District, Guang Zhou, Guangdong, China