TEL. : +86-020 31213735 / E-MAIL : sales@haoairtech.com

We have a team that benefits from over 10 years’ fieldwork and experience

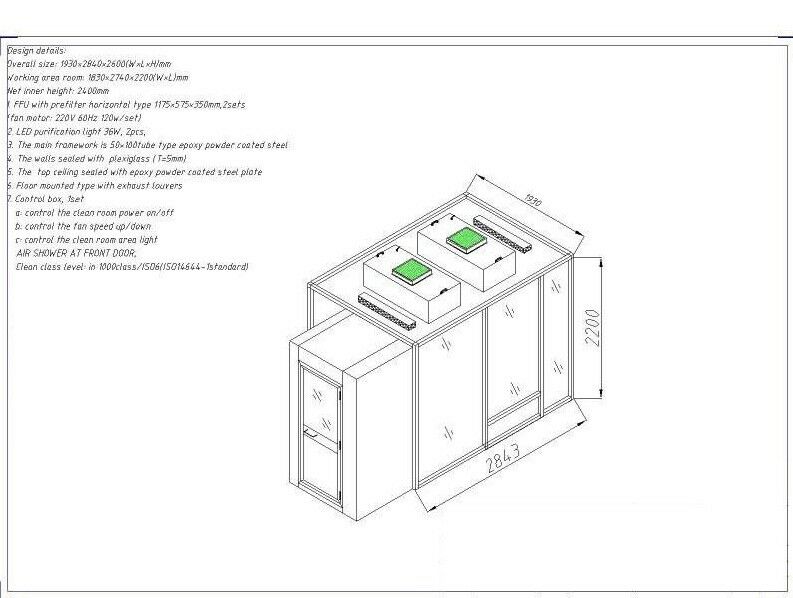

Microelectronics Hardwall Cleanroom

Microelectronics modular hardwall cleanrooms is probably one of the most intensive manufacturing processes, not only for its complexity but for the amount of capital invested. Due to the sensitive nature of the products,

it is critical to construct these modular cleanroom facilities with components which help produce higher product yields.

Moreover, since the number of operations that have to be carried out exceeds the number of available machines, several of these operations are done at the same work centers or tool stations.

Maximizing space and housing specialized equipment is ideally suited for a modular cleanroom system. Each haoairtech modular project begins with a careful needs assessment for

your semiconductor or microelectronics cleanroom. The quality modular cleanroom system is then designed and engineered to specifically fit your application.

And that application usually requires stringent environmental control of a Class 100 Cleanroom, well within the tolerance levels haoairtech can provide.

Given its modular office partitions, haoairtechoffers a structural panel that is light weight, non-particulating and easily modified.

Semiconductor and microelectronics cleanroom systems are designed and constructed to precise standards, labeled and delivered with a

complete set of CAD drawings to make on-site cleanroom installation quick and convenient.

Parameter

| Model | HA-1500 | HA-2000 | HA-3000 | HA-5000 |

| External Size (W*D*H) | 1500*2000*2530mm | 2000*3000*2530mm | 3000*4000*2530mm | 5000*5000*2530mm |

| HEPA Filters | 99.999% efficiency at 0.3 um | |||

| Consumption | 500W | 800W | 1000W | 1600W |

| FFU Nos. | 4 pcs | 6 pcs | 12 pcs | 25 pcs |

| Clean Level | ISO 5 (Class 100), Class A | |||

| Control System | control box | |||

| Rectangular Tube Material | SUS 304 material frame | |||

| Wall Material | Anti-static dustproof curtain | |||

| Blower | Built-in centrifugal blower; speed adjustable | |||

| UV Lamp | Emission of 253.7nanometers, with UV timer | |||

| Air Velocity | 0.1~0.6m/s, average 0.45m/s | |||

| Noise | ≤58db | |||

| Power Supply | AC220V±10%, 50/60Hz; 110V±10%, 60Hz | |||

| Gross Weight | 390Kg | 670Kg | 1100Kg | 2900Kg |

| Package Size (W*D*H) | 2110*930*920mm 2260*660*500mm | 3080*980*1260mm 3080*660*550mm | 3080*980*1260mm 3080*980*1260mm 4080*660*550mm

| 4080*980*1260mm 4080*980*1260mm 4080*980*1260mm 1260*660*1260mm 5080*460*500mm |

| Customized design for clean level, size or material is available | ||||

Copyright © GuangZhou Haoair Purification Technology Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.