We have a team that benefits from over 15 years cleanroon equipment fieldwork and experience.

coldrolled steel dynamic pass box validation with conveyor line for hvac system HAOAIRTECH

1. HAOAIRTECH dynamic pass box validation is of professional graphic design. Our team of talented graphic designers crafts the perfect design, integrating customers' brand into the visual aesthetic of this product.

2. Compared with the other similar dynamic pass box validation , pass box has a lot of advantages, such as static pass box specification .

3. The product is widely used to drown out the noise, eliminate vibration, or protect the equipment from the elements.

Internal size: 600*600*600mm

External Material: steel with power coated (t=1.0)

Inside Material: stainless steel304 (t=1.0)

Locker: Electric interlocking

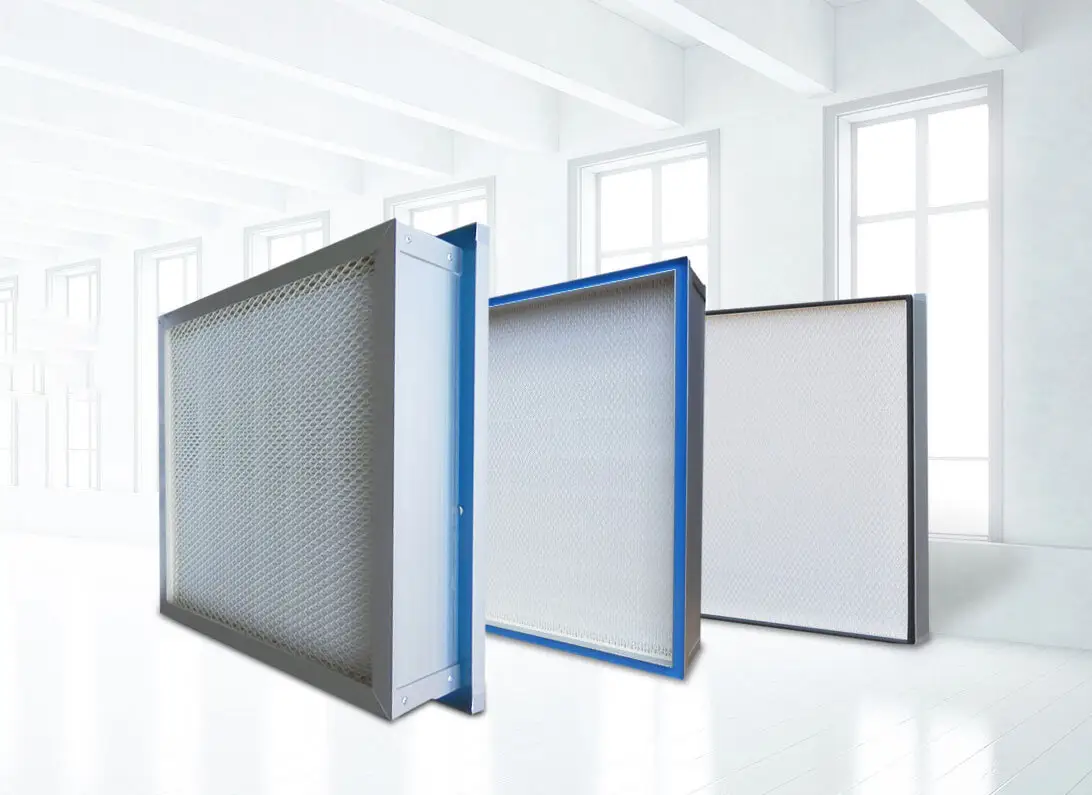

Mini-Pleats HEPA air filter

Air speed: 22-25m/s

MODEL | HA-APB500 | HA-APB600 | HA-APB700 | |||

External size (mm) | 850x500x1350mm | 950x600x1450mm | 1090x750x1600mm | |||

Work zone (mm) | 500x500x500mm | 600x600x600mm | 750x750x750mm | |||

Nozzle | 4 PCS | 4PCS | 6 PCS | |||

Air speed | 18-25m/s | |||||

Material(Option) | 1: Entirety Sus304.(T=1.2/1.0mm) | |||||

Per-filter | 525x275x17mm | 560x275x17mm | 560x275x17mm | |||

G3 | ||||||

HEPA filter | 484x484x69mm | 630x630x69mm | 630x630x69mm | |||

99.99%@0.3um H13 | ||||||

Optional accessories | 1: UV light. 2: Interphone 3:Differential pressure gauge 4: Roller | |||||

Power supply | 0.75KW 380V/50HZ | |||||

packing size (mm) | 1050x780x1600mm | 1100x880x1700mm | 1240x1030x1850mm | |||

Packing material | Standard Export Poly wood Packing(Fumigant free material) | |||||

Illustration

1: power button 2: HEPA Filter 3: Handle 4: Perfilter 5: Fan

Introduce

Pass box with air shower is a kind of assistant equipment for clean room. Mainly be used in passing the small articles between clean room and clean room, unclean room and clean room, which reduce the times of opening door and minimize the pollution extent. It can stop the gas enter the clean room. It also can ensure the goods is clean into in the clean room and reduce the pollution from outside. The blowing time is adjustable with 1 minute , it can save the energy for pass box with air shower. Customized design is available.

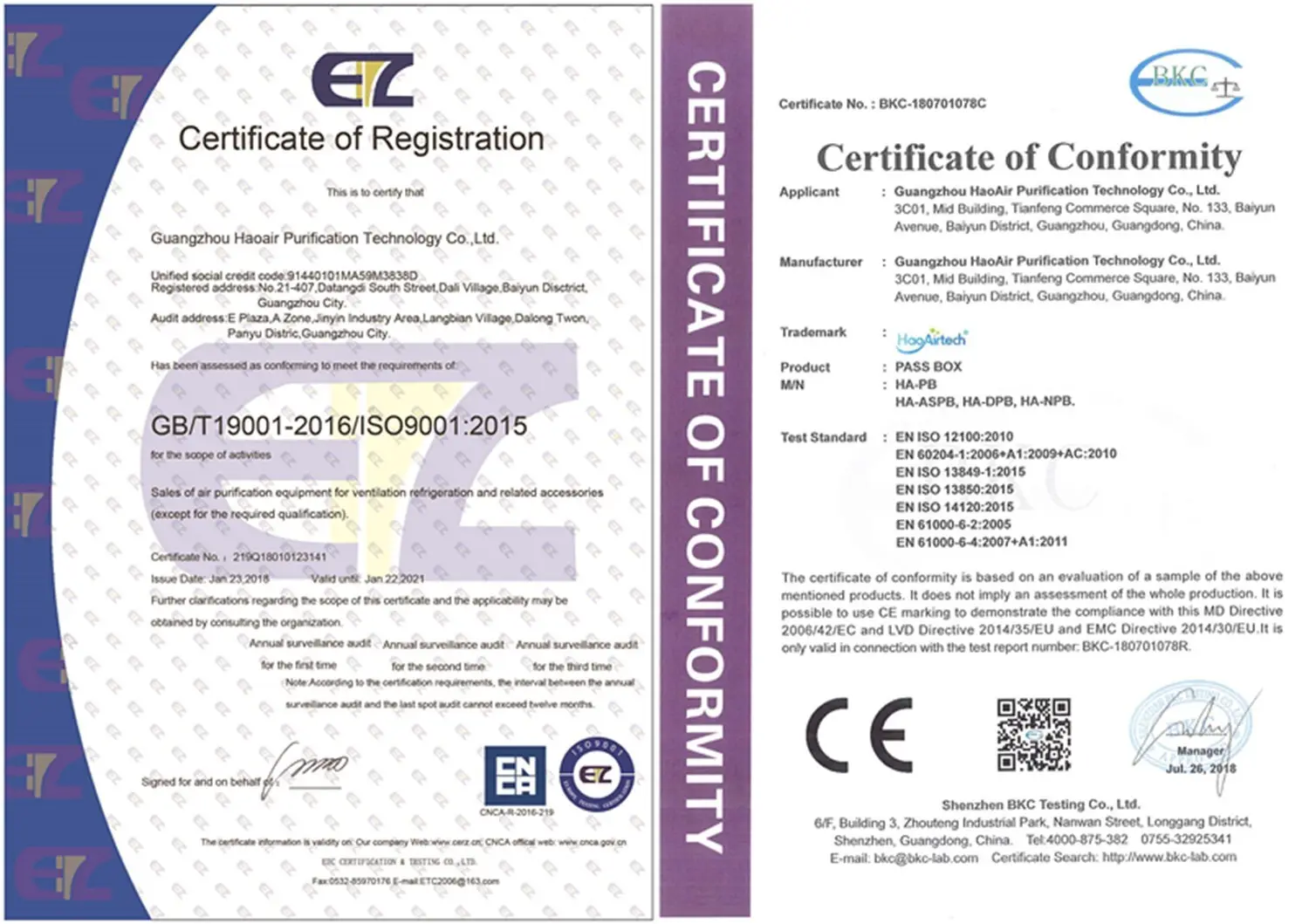

/ Certificated

Our Service

1:Document

A: Document for custom clear: 1 sets

B: Assemble draw: 1 pcs

C: Circuit diagram draw: 1 pcs

D: Test report : 1sets

E: Additional IQ/OQ/PQ document is available upon request.

2: Air Shower Spare Part so that you can replacement in future by yourself:

A: HEPA air filter +Pre-filter (as your request)

Note: HEPA air filter should be replacement in half and one year. Pre-filter

should be replacement in each 6 months, but it can refresh no more than 3 times

B: Sensor (As your request)

C: Control board (as your request)

3: The air shower guarantee time is 2 years excluding consumable parts and accessories .

Company Features

1. Guangzhou HaoAir Purification Technology Co.,Ltd. has been dedicated to the creation, production and sales of pass box .

2. The advanced mechanical processing equipment is available in Guangzhou HaoAir Purification Technology Co.,Ltd.'s manufacturing plant.

3. HAOAIRTECH always insists cleanroom pass box above all. Contact! Sincerity to our customer is the most important in Guangzhou HaoAir Purification Technology Co.,Ltd.. Contact! In the future, Guangzhou HaoAir Purification Technology Co.,Ltd. will uphold the core of dynamic pass box validation . Contact! Guangzhou HaoAir Purification Technology Co.,Ltd. guarantee high quality static pass box specification service for its costumers. Contact!

dust free Clean Room dynamic box Pass through windows

1.The surface material of pass box is cold rolled steel or stainless steel.

2.The inside material of pass box is stainless steel, it can prevent scratches and keeps the pass box flat, neat and wearable.

3.Doors in two sides with mechanical or electronic

It’s widely used in the clean environment, such as: micro-electronics, laboratory, national defense, precise instrument, bio-pharming, optical-electronics, aseptic packaging, etc.

- See more at: http://www.cleanroomffu.com

Application

It’s widely used in the clean environment, such as: micro-electronics, laboratory, national defense, precise instrument, bio-pharming, optical-electronics, aseptic packaging, etc.

Product information

Pass pox with air shower is devised on the basis of the air shower. It keeps the wind spray in 20m/s speed through the stainless steel nozzle after HEPA filter. It’s very significant effect in the filtrate and strong to use.

Product feature

1.The surface material of pass box is cold rolled steel or stainless steel.

2.The inside material of pass box is stainless steel, it can prevent scratches and keeps the pass box flat, neat and wearable.

3.Doors in two sides with mechanical or electronic interlock.

4.Adopt mini-pleated HEPA filter,efficiency:99.99%@0.3μm.

5.The wind speed of nozzle above 20m/s

6.According to production process requirement, it can install efficient sterilization lamp.

OEM

Customized design is available.

Pass Box in producing:

Gargo Pass box type:

Soft touch Microelectronics Control System:

Stainless steel 304 big airflow nozzles:

Packing for exporting:

Factory testing (all the sets you ordered) :

All of equipment is individually factory tested for safety and performance in accordance with international Standards. Each unit is shipped with a documentation outlining the tests undertaken and the unit’s individual results for each unit.

Factory test include:

--appearance testing

--functional test and visual inspection

--electrical safety tests

--air velocity testing

--noise testing

Warranty:

Our equipment is warranty for 1 year excluding consumable parts and accessories.

All equipment is shipped with a comprehensive use’s manual complete with a report documenting all test procedures.

Additional IO/OQ/GMP document is available upon request.

Contact our sales representative for specific warranty details or document request.

Consumable parts illustration:

1: Pre-filter: each one should be replacement in each 6 month, but it can refresh no more three times.

2: HEPA air filter: each one should be replacement in each half and one years.

Standard export packing:

--Stretch film strapped whole cabinet,

--Foam inside protected,

--Plywood case solid fixed

--European standard bottom tray

What you can get from us?

1. Immediately responses for your inquiry and response saving your time, update your project processing.

2. Professional design team matches all your ideas;

3. Over 10years cleanroom, laboratory furniture and air filters producing experience guarantee the quality;

4. Strictly factory testing take out your troubles in advance;

5. ISO, CE, UL,TUV, SGS testing Certificates helped your business;

6. With 18monthes Warranty card service your business in good way;

7. Own the CNC machine, class 10000 clean room workshop, spray booth, 1300*1300 non-gap Mini-plated HEPA filter producing machine as well with over 5years clean room producing experience workers keep well each your orders.

8. Completed of set documents issued with final products help you easy with our products.

Email: sales2@haoairtech.com

Add: RM323 KaiSheng Building,CongYun RoadYongping street ,Baiyun District, Guang Zhou, Guangdong, China