We have a team that benefits from over 15 years cleanroon equipment fieldwork and experience.

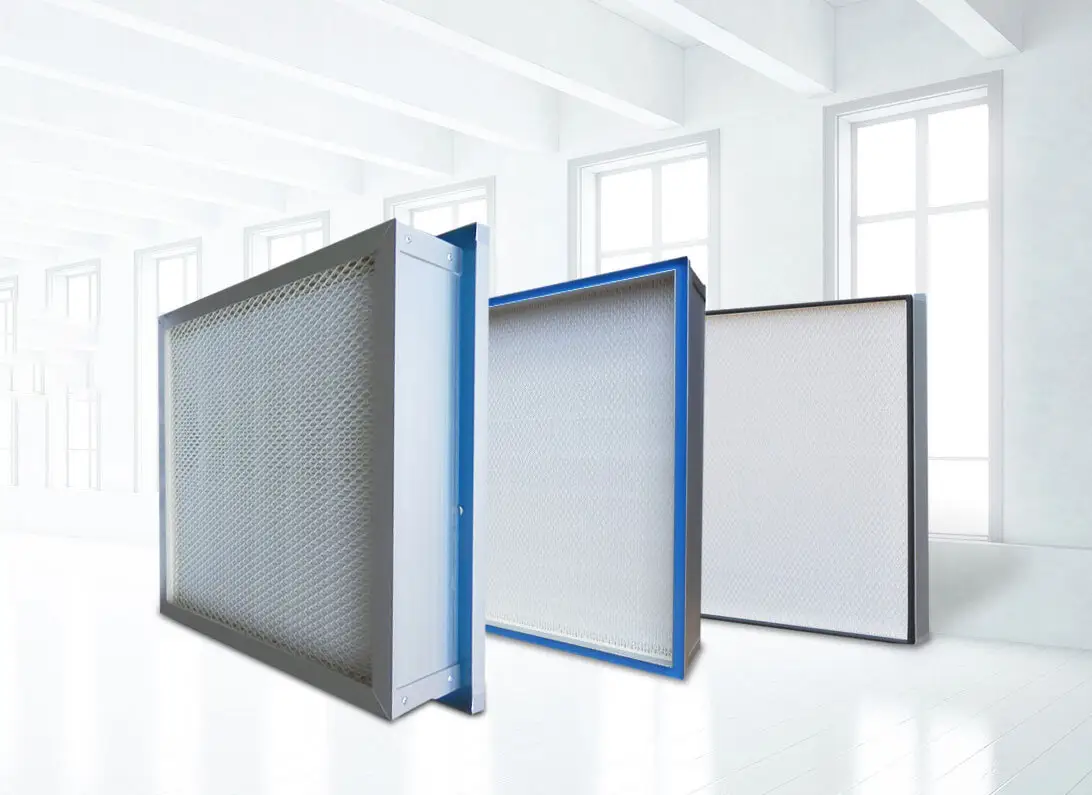

HAOAIRTECH v bank hepa filter h12 with flanger for electronic industry

It is patent technology to ensure the V type passage in low resistance.

Neoprene /EVA or PU gasket prevent the air leaking in operation.

Extrude and anodized aluminum frame in 50mm, 69mm, 80mm, 90mm for choose.

While color metal screen to protect the filtration media without any damage.

Light weight and easy to install

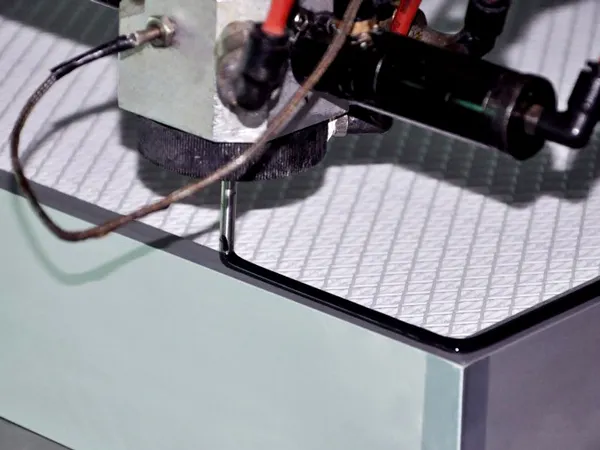

Adopting the laser to scan the filter one by one ( MPPS).

100 % provide the test report for each mini-pleats HEPA air filter

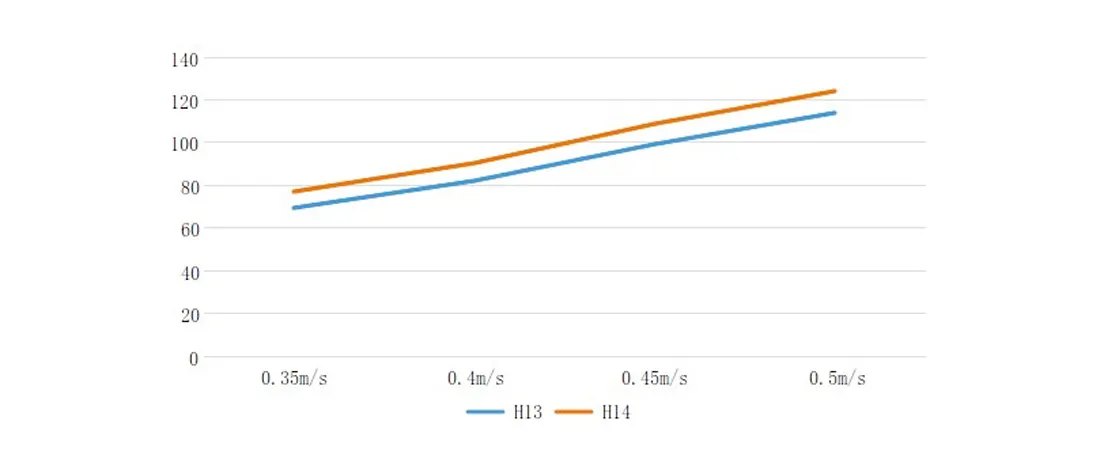

Filtration Efficiency: H13 ,H14,(EN1822). 99.95%-99.995%@0.3um

Applied to the terminal filtration of the air-condition filtration system

Media | Super glass fibre |

Frame | AL/GL/SUS201/304 frame |

Gasket | Neoprene /EVA or PU |

Media spacer | Hot melt |

Frame thickness (mm) | 46/50/69/80/90/96/120 |

Screen | Metal screen |

Efficiency | >99.999%@0.3um |

Max Temperature | 70℃ |

Max Humidity | 100% |

Dimension(mm) | Rate Air Flow | Media Area | Dust Holding | Rate primary | Finally |

320X320X50 | 200 | 1.99 | 120 |

H13 :<200Pa |

400-600pa |

484X484X50 | 450 | 4.51 | 270 | ||

610X610X50 | 700 | 7.13 | 430 | ||

915X610X50 | 1000 | 10.58 | 650 | ||

1170X570X50 | 1200 | 12.57 | 750 | ||

1220X610X50 | 1350 | 14.04 | 850 | ||

320X320X69 | 250 | 2.89 | 180 | ||

484X484X69 | 600 | 6.55 | 400 | ||

610X610X69 | 1000 | 10.37 | 620 | ||

915X610X69 | 1500 | 15.39 | 920 | ||

1170X570X69 | 1800 | 18.28 | 1100 | ||

1220X610X69 | 2000 | 20.41 | 1230 | ||

484X484X96 | 1000 | 10.24 | 620 | ||

610X610X96 | 1500 | 16.2 | 980 | ||

915X610X96 | 2300 | 24.01 | 1450 | ||

1170X570X96 | 2800 | 28.56 | 1720 | ||

1220X610X96 | 3100 | 31.89 | 1920 |

Application

Mini-pleats HEPA air filter suitable for hospital, electronic industry ,food,Pharmaceutical , bioengineering,precision instrument, electron semiconductors and dust-free room, national defense,aerospace field, fan filter unit, HEPA unit , air shower, dynamic pass box, dispensing booth ,softwall cleanroom, laminar flow booth and so on .

Our Service

1: 100% scann air leaking test for each Mini-PleatsHEPA air flter, test report accompany all of

HEPA air filter.

2: 2 pcs in one carton .each air filter warp by PE Bag .

3: Small order is polywood packing so that we can send out by sea in LCL.

4: If order amount more than 20000USD, We accept the 100% LC at sight against with

document.

5: Free sample possible for you confirmation of quality .

Email: sales2@haoairtech.com

Add: RM323 KaiSheng Building,CongYun RoadYongping street ,Baiyun District, Guang Zhou, Guangdong, China