We have a team that benefits from over 15 years cleanroon equipment fieldwork and experience.

HAOAIRTECH high efficiency cleanroom systems with constant temperature and humidity controlled for semiconductor factory

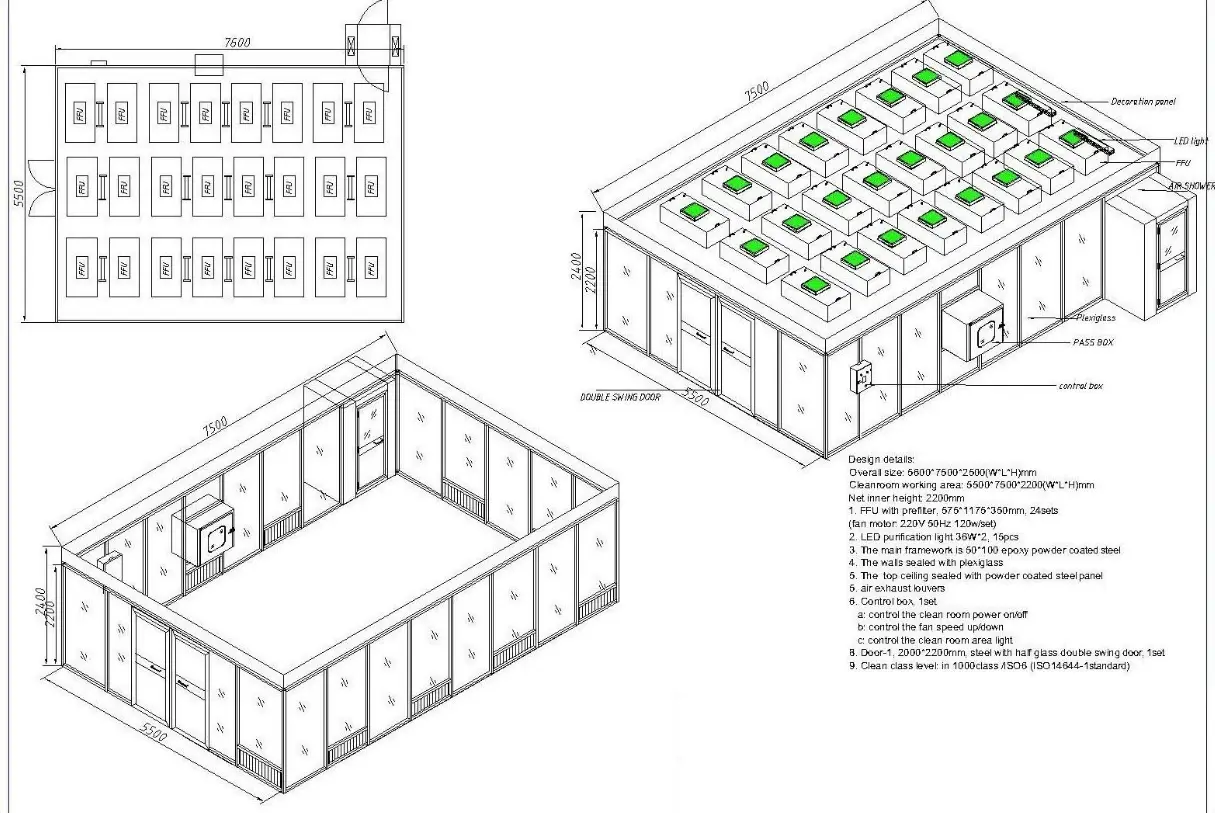

Modular Cleanroom Systems

Once Through Design

Once-Thru Design is also known as single pass. Ambient air is drawn into the Fan Filter Units at ceiling level. The filtered air passes into the cleanroom and is transferred out of the room through grilles at the bottom of the walls..

Recirculating Design

Recirculating cleanrooms are ideal when temperature or humidity control is required.

Conditioned air inside the plenum space is drawn into the Fan Filter Units and the filtered air then passes into the cleanroom. Air from the cleanroom is forced into the return air grilles located in the lower wall sections and is recirculated up the return air chases within the walls to the plenum. Air is mixed with make-up air inside the plenum and drawn thru the fan filter unit units again.

How Are Cleanroom Standards Determined?

The number and size of particles allowed in the room determines the classification of air cleanliness.

As the process in the cleanroom grows less critical, greater quantities of invisible particles may be present without risk, thus the numerical classification of the cleanroom will be higher.

The simple designations of the early U.S. Federal Standard 209, in which a class number was a statement of the number of 0.5 micron particles per cubic foot of air, are gone.

Although Federal Standard 209 is most commonly used in the United States, it is now officially retired as of late November, 2001.

The ISO 14644-1 document became mandatory in the European union on November 1, 1999 and is now the worldwide baseline measurement for cleanrooms.

Organizations with ISO 9000 certifi cation are now required to utilize ISO 14644-1 for defining clean spaces.

Guidelines For Selecting Filters

During the initial quotation, design and engineering phases our staff will make the calculations necessary to achieve the desired ISO or U.S. Federal Standard 209 Class. The

correct quantity of HEPA or ULPA grade filters will be selected using air changes per hour as the most effective method for meeting class requirements. Right from the

start our staff will work with your technical staff to determine if extra-ordinary design issues must be addressed.

Installation, Testing and Certification

Customers with in-house contracting or installation capability appreciate the simplicity and easy installation of the modular Cleanroom Systems.

A network of Authorized Installers enables Clean Rooms International to offer complete installation services. Testing and certification by an independent contractor can be

arranged as well.

Whether you choose to install a room yourself or use a Authorized Installer, our staff serves as a liaison and guides the construction or installation process.

Email: sales2@haoairtech.com

Add: RM323 KaiSheng Building,CongYun RoadYongping street ,Baiyun District, Guang Zhou, Guangdong, China