We have a team that benefits from over 15 years cleanroon equipment fieldwork and experience.

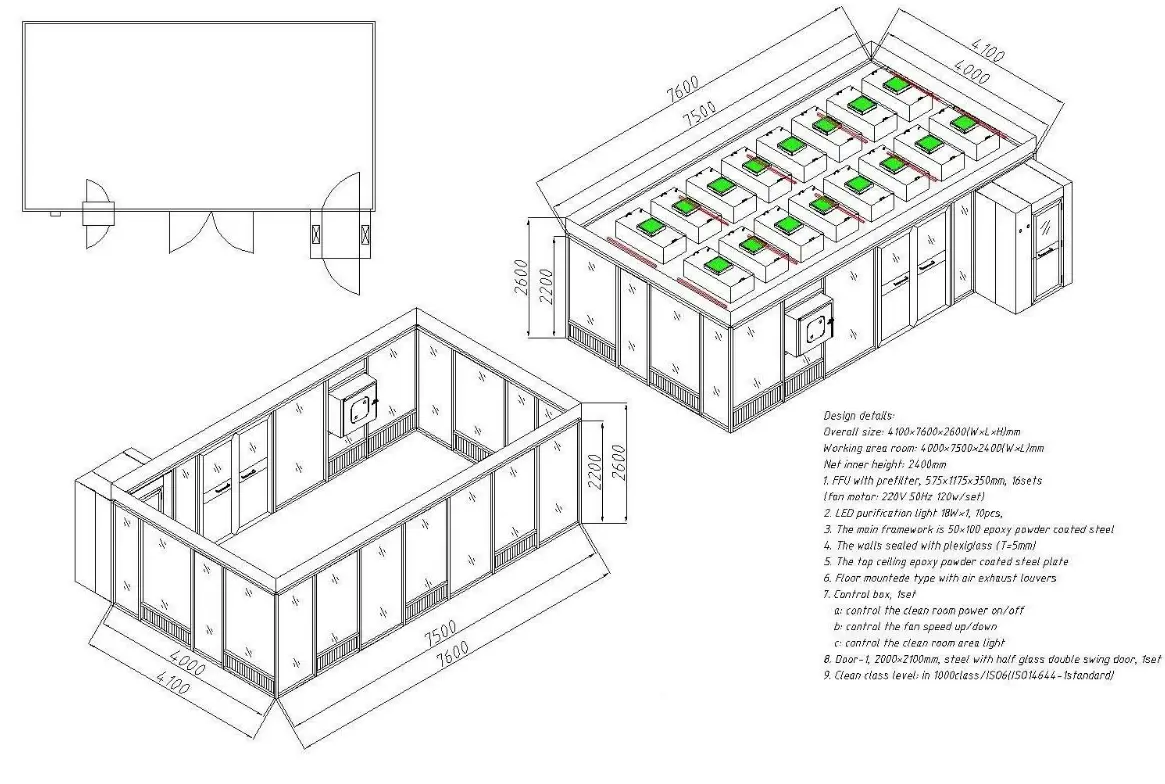

HAOAIRTECH clean room construction enclosures for semiconductor factory

Modular Cleanroom Construction

Provides Controlled Environment

Haoairtech Hardwall Cleanroom Wall Panels and Components are engineered to provide a secure controlled environment within the cleanroom.

Ultra-smooth surface wall panels, framing and ceiling components assure consistent pressure in the cleanroom and constant control of air-born particles. As a result, Cleanroom Systems achieve very high cleanroom performance standards.

Non-Progressive Design

The Haoairtech wall panel and framing modular design reduces lead time which assures that the cleanroom is in operation ontime and within budget. As needs change in the future, haoairtech wall panel modular design offers the ability to relocate or expand the cleanroom in the future.

Special Sizes

Haoairtech wall panel composition and the modular panel construction fulfills requirements for any hardwall cleanroom design and layout. Wall panels can be made in special sizes for entry areas, gowning rooms and air-locks,

ensuring that the cleanroom pressure remains constant. Extra-high Legend wall panel systems can accommodate large equipment which require ceilings higher than the standard eight (8) feet.

Load Considerations

Three factors are considered when determining which wall system to use for load-bearing cleanrooms.

The first factor is the amount of total weight on the cleanroom wall,

the second factor is the span distance between all four (4) of the cleanroom walls and the third factor is the height of the wall.

Consult with the factory for detailed information about your cleanroom project.

Email: sales2@haoairtech.com

Add: RM323 KaiSheng Building,CongYun RoadYongping street ,Baiyun District, Guang Zhou, Guangdong, China