We have a team that benefits from over 15 years cleanroon equipment fieldwork and experience.

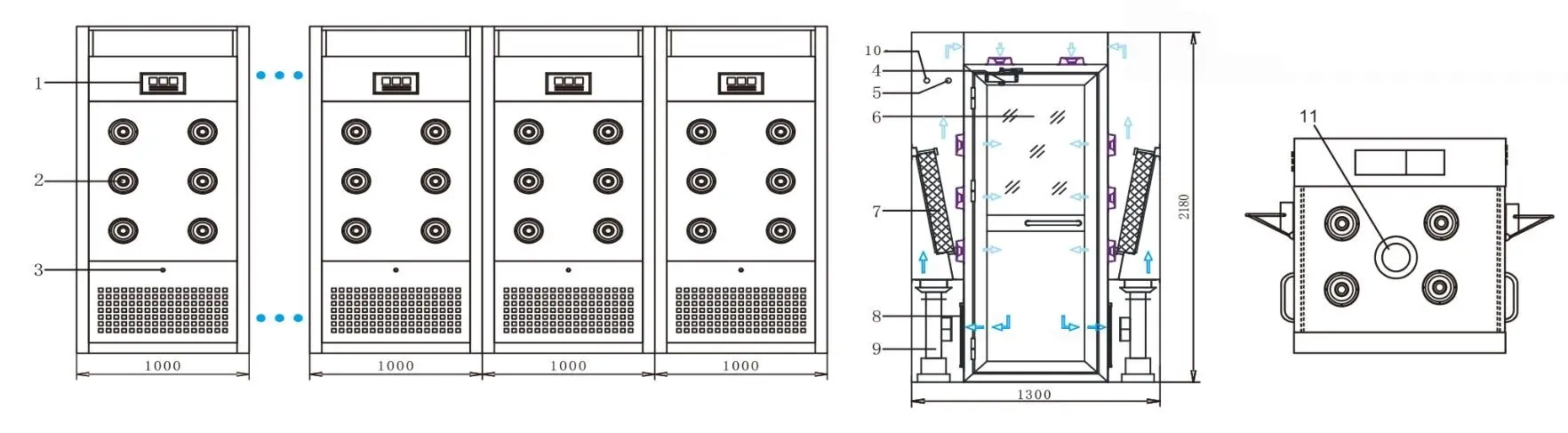

fast rolling clean room manufacturers with three side blowing for large scale semiconductor factory

External Material: steel with powder coated (t=1.0)

Inside Material: stainless steel304 or steel with power coated (t=1.0)

External size: 1300*1000*2180mm

Internal size: 800*930*1910mm

Sus nozzle: 16pcs

Blowing way: 3 side (left, right and top)

Air speed: more than 25m/s

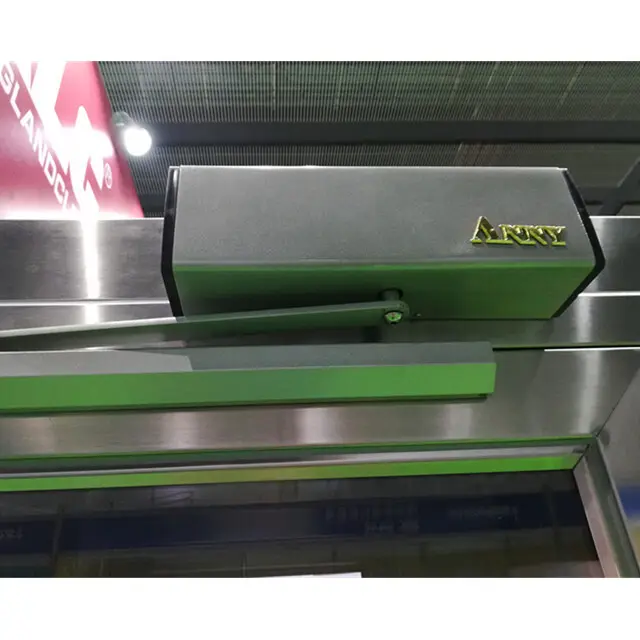

Door: Electric Interlocking in both side.

MODEL | HA-AS1300P1 | HA-AS1300P2 | |

External size (mm) | 1300x1000x2180mm | 1300x2000x2180mm | |

Work zone (mm) | 800x930x1910mm | 800x1930x1910mm | |

Capacity Per cycle | One or Two person | Two or Four person . | |

Material (Option) | 1: External is steel with power coated, Internal is SUS304(T=1.0/1.2/1.5mm) | ||

Control system | 1: Control system with LED display for the shower time. | ||

The power of fan | 380V/50HZ/0.75KW | 380V/50HZ/0.75KW | |

Air flow of fan(m3/h) | 1500 | 1500 | |

Fan run (r/min) | 2800 | 2800 | |

Nozzle in stain less steel | 16 pcs | 32pcs | |

Wind speed(m/s) | >25m/s | ||

Noise level(dB) | <75dB | ||

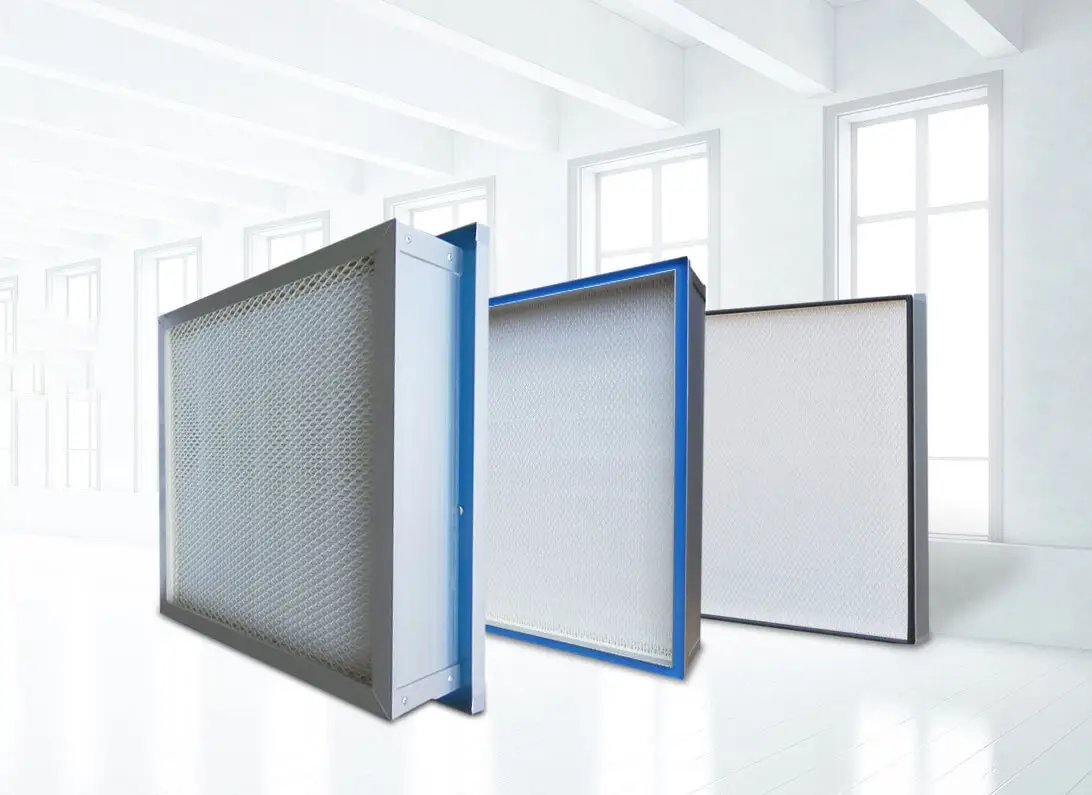

HEPA FILTER | Size(mm) | 630X630X80mm | 630X630X80mm |

Efficiency (%) | 99.995% @ 0.3um mini-pleats HEPA Air Filter | ||

Air velocity | 1000(m3/h) | ||

Initial resistance(pa) | <180pa | ||

Pre-filter | Size(mm) | 775x380x17 | 775x380x17 |

Efficiency (%) | 75% @ 0.5um | 75% @ 0.5um | |

G3 | G3 | ||

resistance(pa) | <30 Pa | <30 Pa | |

parameter | Power supply | 380v/50HZ 3P | 380v/50HZ 3P |

Net power(kw) | 3 kw | 4.5 kw | |

packing size (mm) | 1400x1200x2280mm | 1400x2200x2280mm | |

Packing material | Standard Export Poly wood Packing(Fumigant free material) | ||

Weight | 330kgs | 660kgs | |

Illustrate

1: Control Board 2: SUS Nozzle 3: Infrared Indicator 4: Emergency switch 5: Working light 6:Glass window 7: HEPA air filter 8: Blower 9: Per-filter (H13 99.995%@0.3um) 10: Door closer 11: Purification light

Application

The cargo air shower is one of the goods buffer passages that enter the clean room. It can minimize the pollution caused by commodity or goods entering and out of the dust free room. The equipment for showering the goods is commonly known as the cargo shower room;. The cargo air shower is part of the cargo passage. It has been applied in many fields, such as food and beverage, biochemistry, precision instrument, electronic, photoelectric, microelectronics, fiber optic cable, precision machinery, biopharmaceutical, aeronautics and Astronautics and so on.

/ Certificated

Our Service

1:Document

A: Document for custom clear: 1 sets

B: Assemble draw: 1 pcs

C: Circuit diagram draw: 1 pcs

D: Test report : 1sets

E: Additional IQ/OQ/PQ document is available upon request.

2: Air Shower Spare Part so that you can replacement in future by yourself:

A: HEPA air filter +Pre-filter (as your request)

Note: HEPA air filter should be replacement in half and one year. Pre-filter

should be replacement in each 6 months, but it can refresh no more than 3 times

B: Sensor (As your request)

C: Control board (as your request)

3: The air shower guarantee time is 2 years excluding consumable parts and accessories .

Email: sales2@haoairtech.com

Add: RM323 KaiSheng Building,CongYun RoadYongping street ,Baiyun District, Guang Zhou, Guangdong, China