We have a team that benefits from over 15 years cleanroon equipment fieldwork and experience.

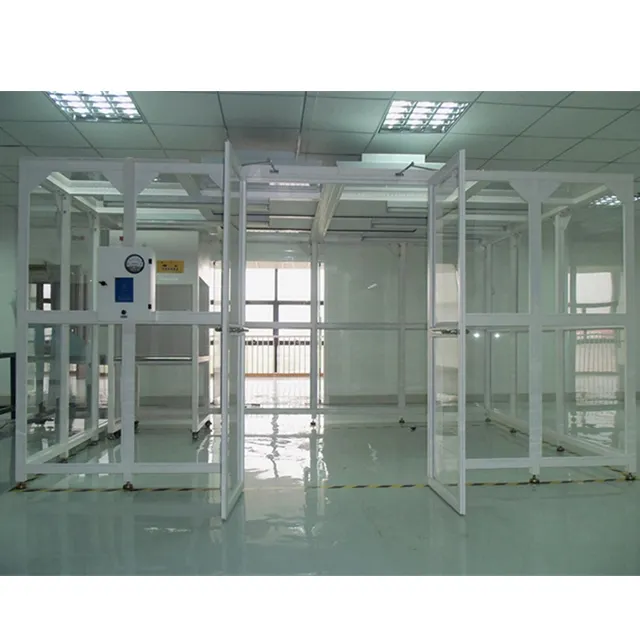

portable clean room design vertical laminar flow booth for sterile food and drug production

- To provide faster and better service, HaoAir constantly improves the service quality and promotes the service personnel level.

1. HAOAIRTECH clean room design is designed and optimized exclusively. Many factors which affect its performance such as materials, air circulation parts, housing finish are all considered during its design.

2. The product is in compliance with some of the toughest quality standards across the world.

3. This product will allow people to make a stylish statement to others. It greatly helps show off people's personal style.

Class100 Clean Shed For Cleanroom

Introduction:

A Clean shed rooom or clean room is an environment,

typically used in manufacturing or scientific research, that has a low level of environmental pollutants such as dust, airborne microbes, aerosol particles and chemical vapors.

More accurately, a cleanroom has a controlled level of contaimination that is specified by the number of particles per cubic meter at a specified particle size.

To give perspective, the ambient air outside in a typical urban environment contains 35,000,000 particles per cubic meter in the size range 0.5um and larger in diameter,

corresponding to an ISO9 cleanroom, while an ISO1 cleanroom allows no particles in that size range and only 12 particles per cubic meter of 0.3um and smaller.

For clean room doors, we have many styles, this product uses stainless steel door.

The open way we have automatic sensing and manual door opening.

Stainless steel doors are highly resistant to corrosion and abrasion.

It is a particularly popular material.

Technical Paremeters:

| MODEL | HA-LFB2000 | HA-LFB3000 | HA-LFB4000 | HA-LFB5000 |

Ex size (mm) (W*D*H) | 2000X2000X2596 | 3000X3000X2596 | 4000X4000X2596 | 5000X5000X2596 |

| In size (mm) | 1900x1900x2205 | 2900x2900x2205 | 3900x3900x2205 | 4900x4900x2205 |

| Purification rank | Class100-300,000(FS209E USA) | |||

| HEPA filter | Efficiency : 99.99% @ 0.3um - 99.999% @ 0.12um (MPPS) | |||

| Pre-filter | Efficiency : 85% @ 5um | |||

| Control system | PC control system / promised speed by control box | |||

| Pressure Gauge | American Dywer pressure | |||

| Noise | <50-55 dB (test point distance is 1m) | |||

Air velocity(m3/h) | 0.2-0.5m/s Adjustable (test point distance is 30cm) | |||

| Frame material | stainless steel/steel with power coated/Cast aluminum profile | |||

| Wall frame | Tempered glass / PVC anti-static curtain (option) | |||

| Fan | EBM Fan /Taiwan fan/ Domestic fan (option) | |||

| Power suppler | AC110/220v 50HZ/60HZ | |||

Customer's design is avaliable!

Feature:

Standard product

• FFU : galvanized case;smooth surface finish and rust-free

• HEPA filter : HEPA filters comply with EN 1822;efficency is available from H13 to U17

• Frame : frames are made of sus stainless steel square pipe.they are good looking and anti-corrosive

• Buliding envelope : wall is made of anti-static,soft PVC or acrylic

• Control box : control box is controlled by computer programs.parameters are easy to be adjusted.

Alternative configuration

• Pressure difference control device;

• Pass box;

• Air shower pass box;

• ULPA filter;

• Sticky mat;

• Air shower;

• Transparent/grid pvc curtain;

• Clean bench;

• Thermo-static and humid -static air conditiong system

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Company Features

1. Guangzhou HaoAir Purification Technology Co.,Ltd. has won the market's appreciation with the spirit of self r&d and self-innovation. We are a professional manufacturer supplied with modular clean room development and production.

2. Our company consists of management members with proven track records from the industry. Together they bring a wealth of complementary experience, knowledge, and skills to promote our business.

3. Our goal is to create and develop high-value resource opportunities by aligning our business strategies through disciplined operational excellence and cost-efficiency. We always act responsibly, grow our business, and maintain continuous contact with our customers and partners. It is important that our customers can always rely on our products and services. Welcome to visit our factory! Our company is committed to climate action, including reducing energy demand and greenhouse gas emissions associated with our products and operations. Regardless of the political perspective, climate action is a global issue and a problem for our customers to demand solutions. Welcome to visit our factory!

Email: sales2@haoairtech.com

Add: RM323 KaiSheng Building,CongYun RoadYongping street ,Baiyun District, Guang Zhou, Guangdong, China